Geosynthetica welcomes field experience stories.

Contact the Content Director, Chris Kelsey, here.

By Carl Charpentier – The use of Electrical Leak Location (ELL) technologies on geosynthetic containment installations is said to have started in the early 1980s. It was offered by only a few companies and on very specific projects. This resulted in little promotion of the service and, thus, little demand for what is otherwise a very useful and important service.

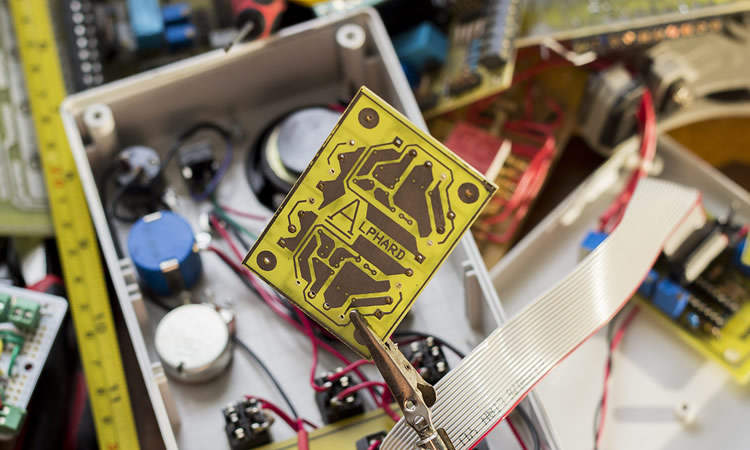

As such, for many years the field lacked sustained investment in research and development of ELL technology. Even today with a far more mature market and more practitioners learning how to specify and conduct ELL surveys, we still find just a small number of companies dedicated to innovating and practicing leak location. These companies often make their equipment in-house.

I have been a bit of a rarity in the geosynthetics field, having committed my entire career to date—more than 20 years!—to leak location equipment improvement and field projects.

These days I serve as the Technical Lead at Groupe Alphard out of Montreal, Canada. Being dedicated to a “niche” technology in the geosynthetics field has brought me a number of benefits, not the least of which is experience. It has introduced me to top-tier companies and practitioners around the world, through presentation, standardization, and project opportunities. While most of my field work has focused on the Canadian market, I have enjoyed implementing leak location on sites in Egypt, the USA, Chili, France, Ireland, Guadeloupe, Portugal, and even Reunion Island near Madagascar.

EARLY DAYS IN LEAK LOCATION

I started in 2001 at Solmers (later acquired by WSP Canada) as an Electronic Technician to assist in the development of new leak location technologies. The equipment Solmers had developed was basic and I could see the possibilities in the ELL science. It simply needed a little innovation to support the growth of methodologies such as the water puddle method and the use of dipole equipment.

It was an exciting opportunity, with so much potential adoption in the field. In these early years of my career, I was given a lot of freedom to work on new equipment, improve maintenance strategies, and hone adaptations that would enable the technology to be more readily implemented in the field.

After grasping the fundamentals and improving existing equipment, moving from the lab to the field was a natural progression. If equipment was to break down during a survey, I wanted to be able to repair it immediately. If an operator was struggling with performing a survey, I wanted to be able to identify the problem—if it was environmental, a boundary condition, how the equipment was being handled, etc.

RELATED: GeoCreatives Series – Carl Charpentier and Abigail Gilson

Whether an electrical technician was really needed on site was something of a running gag within the team, but the merit of applying a lab understanding of the equipment in the field became very apparent and real during a 2007 project in Egypt. The dipole power source suddenly malfunctioned likely caused by a screw that came loose from the long flight’s turbulence and short-circuited the power transformer.

Understanding how the equipment was put together helped me adapt the electronics, using some simple parts from a local store in Alexandria. The job was able to be finished without a lengthy delay (such as shipping equipment overseas for evaluation!).

A FIELD ABOUT TO EXPAND

My initial experience getting my boots dirty in the field came at a great time. The technology was improving quickly with more use, more investment, more standardization interest. The advancements made in the water puddle method resulted in a simple and reliable way to survey uncovered geosynthetic lining systems.

The main challenge we found was developing a dipole methodology for covered membranes. No universal method would work in every circumstance. Each site was different due to its type of natural material, layer thicknesses, homogeneity, electrical isolation, weather, and so forth.

The equipment used by Solmers in those early days was not what I would characterize as elaborate, but it was very effective at locating leaks in a geomembrane. Interpreting the dipole method data, however, required more expertise. That was a concern. It also revealed another place in which the overall field needed to invest resources for training operators. Properly producing the dipole data, for example, required a strong understanding of the ideal placement for the injection electrode, the best direction to survey in, and how to build a voltage map for displaying results.

During this period, I had the good fortune to meet Abigail Gilson-Beck, who was at the time working for Vector Engineering (later acquired by Ausenco). Vector was very interested in advancing its use of leak location and Abigail was turning toward specializing in it. Solmers and Vector established a partnership and I got to share knowledge and field experiences with another professional dedicated to growing ELL technology.

Carl was part of the original crew that I learned electrical leak location methods from and we have become great friends over the many years of our parallel career paths. Carl is obviously multi-talented but even better than that, he is a great person. I can always count on him for honesty, kindness and humor.

-Abigail Gilson-Beck, P.E., TRI EnvironmentalNOTE: Gilson-Beck will lead a half-day, live, online training session on ELL technology on May 10, as part of TRI Environmental’s CQA Week Online Courses.

I continue to enjoy helping to develop the global understanding of the ELL process, through my involvement with the geosynthetic community, standardization development with ASTM Committee D35 on Geosynthetics, and technical papers and presentations. I think fondly of how I was able to get into publishing on leak location with the help of Prof. André Rollin, who contributed so much to the field. He served as co-author on my first publication in 2009 for a geomembrane convention in France. This led to another international paper opportunity for me in 2010 in Chile.

(More of my professional publishing is available on my LinkedIn page. I welcome your contact!)

CHARPENTIER ON STAYING ACTIVE

In January 2012, I had the opportunity to join Groupe Alphard, where I still work, and apply my first decade of ELL knowledge to project management. Importantly, the company gave me the chance to market the technology more and participate in standards development. I have continued to write papers—13 to date, many of which are available here—and joined ASTM Committee D35 on Geosynthetics.

If you have not taken part in ASTM, I recommend it. The contributions you can make to the global field are extremely valuable to growing whatever niche you might work in. With leak location, ASTM standards development and refinement have been enormously important.

My dedication to innovation over the past 20 years has aided in the development and understanding of Electrical Leak Location technologies on a larger level than just in my own companies. That, I think, is what we should each strive for, especially in a field like geosynthetics. I plan to continue refining my understanding of how leaks develop in lining systems and how to locate and correct them. This work, like the work of designers, manufacturers, and installers, preserves our environment by continually improving leak location technology. I am passionate about sharing my findings with the community to help society better understand the value in Electric Leak Location Surveys.

If you are interested in knowing more about ELL or have questions about a specific project, please contact me via LinkedIn or Groupe Alphard.

Carl Charpentier is Geomembrane Leak Location Expert & Team Leader for Groupe Alphard. Learn more about his work and his company’s work at www.leak-location-alphard.com.