Airport pavements must be stringently engineered to meet regulations, ensure passenger and personnel safety, and handle tremendous loads of modern aircraft. Rehabilitation works provide excellent opportunities for airport authorities to make the changes that can serve the next phase of performance and safety requirements. At Croatia’s Pula Airport, that is precisely what they did in 2020. Asphalt concrete pavements were scheduled to be rehabilitated, so the project owner used the opportunity to install a geosynthetic composite reinforcement solution in the pavement system.

REINFORCING PULA AIRPORT

Asphalt reinforcement has been an increasingly popular strategy with airport projects. The use of a geosynthetic in the asphalt system improves the elastic modulus of the pavement for better load distribution, guards against wheel rutting, and mitigates reflective cracking for safe, long-term performance.

For Pula Airport, this was a valuable option. In just five years, the passenger traffic had doubled to around 800,000. The sudden quiet in travel in 2020 due to covid enabled the airport to address the upgrades necessary to support continued growth in air traffic volume.

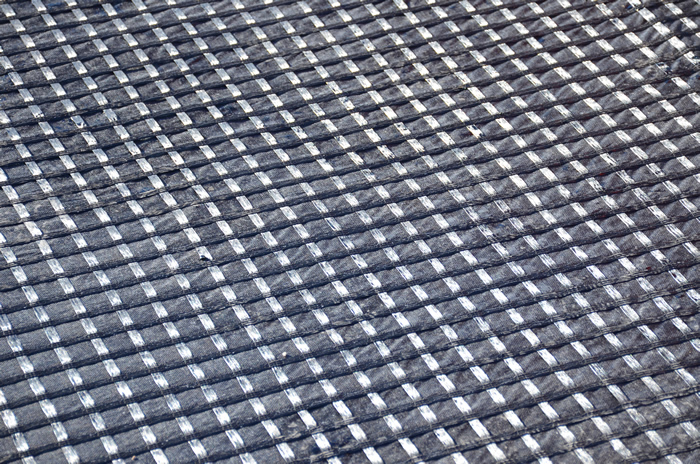

DUALTEX GLASS, manufactured by Belarus-based Mahina-TST, was specified for the site. Uniquely, the material is a double-layer composite reinforcement, featuring a glass geogrid with bitumen coating and a nonwoven polypropylene substrate impregnated by bitumen dispersion.

MORE GEO: Podcast #24 – Fully Biodegradable Materials Mimic Geosynthetics

For the installation, the existing top asphalt concrete layer was removed and the reinforced geocomposite was installed atop the prepared base pavement.

This involved the cleaning of the existing asphalt concrete pavement from dust and dirt after milling and the sealing of joints and cracks with bitumen. A C60 BP5 bitumen-polymer cationic emulsion was used as a binder for priming the base (bitumen content of emulsion is more than 60%). The geocomposite was installed atop the prepared layer with the use of a forklift and special rolling device. Finally, 6 cm of asphalt concrete pavement was made by two wide-span road rollers.

Compounds were used where required to ensure the evenness of the apron.

For more information about Mahina-TST’s geosynthetics and international network, visit www.mahina-tst.com.